ANTI LOCK BRAKING SYSTEM DRIVER

In the racing world driver aids such as ABS and traction control systems (TCS) take on different roles. Decreased stopping distance is not guaranteed by ABS and is a secondary effect. In ideal conditions vehicles equipped with ABS generally experience shorter stopping distances than those without.

ANTI LOCK BRAKING SYSTEM DRIVERS

But to help drivers maintain control of their vehicles in heavy braking situations. The primary purpose of ABS is not actually to help cars stop faster. Motorcycles equipped with ABS are also 37% less likely to be involved in a fatal crash, according to a study by the Insurance Institute for Highway Safety (IIHS). Nonfatal crashes have reduced by 6% in cars, and by 8% in LTV's.

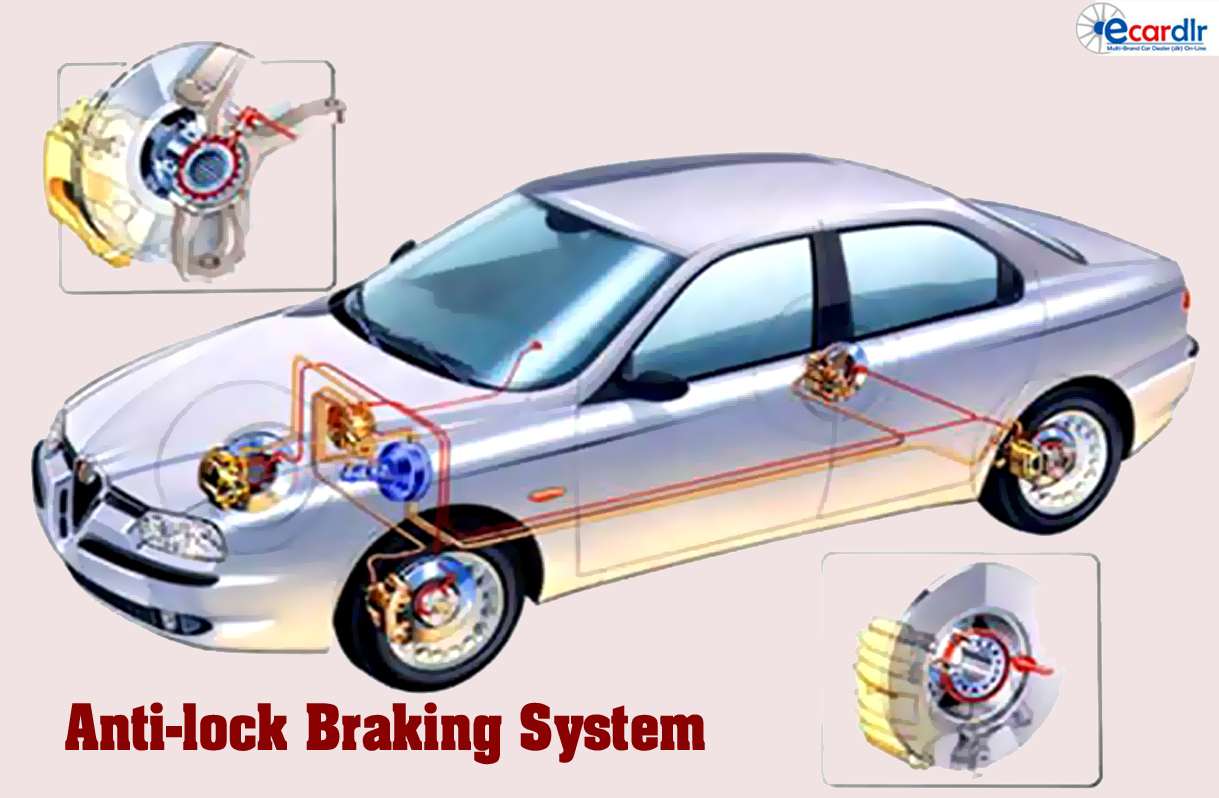

Controller - The electronic control unit (ECU) is the brain of the ABS and uses data from the sensors to determine whether or not to pump the brakes.Pump - These pumps are filled with hydraulic fluid and apply pressure to the brake drums or callipers on demand.Valves - Valves in the brake line allow, block and release pressure on the brakes by assuming three different positions.

Speed sensors - These sensors monitor how fast the wheel or wheels are rotating.

The four major components of a typical anti-lock braking system are: Today, anti-lock braking is now standard on virtually all new cars and motorcycles and is used not only to aid steering whilst braking but also to help with traction control. Although, it wasn't until the 1970's that ABS was adapted and introduced to the commercial vehicle market on a large scale. The first primitive form of ABS was developed in the 1920's by French pioneer Gabriel Voisin, initially to aid braking on aircraft. Commonly known as ABS, or sometimes anti-skid braking systems, anti-lock braking systems help prevent car and motorcycle wheels locking up and improve steering control whilst braking.

0 kommentar(er)

0 kommentar(er)